Why High-Shear Dry Extrusion Improves Poultry Digestibility

The amino acids that make up proteins are critically important in any diet. Typically, in order to build proteins, all amino acids are needed. Commercial diet formulations often focus on levels of lysine and methionine, as these tend to be limiting to growth and efficiency.

However, when working on least-cost diet formulations, other amino acids often come into play as well.

There are two sulfur-containing amino acids that make up proteins – methionine and cysteine. The sulfur component is important because it helps proteins stick together and form structures, which give them function. While there are a number of functional proteins in soy, one such group is known as antinutritional factors, which are similar to trypsin inhibitors. Antinutritional factors serve as a natural defense mechanism for soy, making protein digestion difficult and dissuading animals from eating it. Therefore, heat processing like high-shear dry extrusion, which deactivates trypsin inhibitors and other antinutritional factors, is needed to make high-quality soy meals that enhance animal growth.

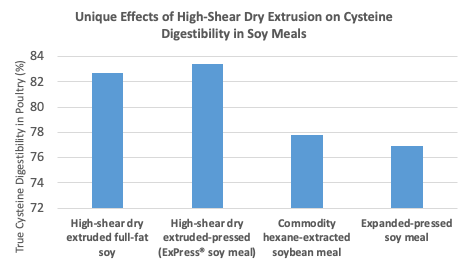

It should be noted that one type of heat processing does a markedly better job of promoting digestion of sulfur-containing amino acids more than others: High-shear dry extrusion. In the case of cysteine digestibility, high-shear dry extrusion is far superior to other methods (data from Dr. Carl Parsons, University of Illinois).

As seen in the graph above, high-shear dry extrusion does something unique to free up cysteine in soy proteins. Digestibility that improves by 5-6% indicates a major advantage from processing. The heating process for hexane extraction and those achieved with expanders produce very different results, making access to cysteine during digestion much more difficult.

Remember that cysteine is used in proteins to give structure and function, and one important group of proteins in soy is the trypsin inhibitors. As seen here, one soy trypsin inhibitor contains seven cysteine pairs that make the protein stick together and function, causing difficulty during protein digestion. Vastly improved cysteine digestibility following proper processing with high-shear dry extrusion can also indicate better antinutrient deactivation, providing a higher-quality meal. Additionally, feathers are rich in these amino acids, resulting in high requirements for chickens.

What does this mean for formulations? When using high-shear dry extruded soy meals in, for example, broiler formulations, premiums can be realized anywhere from $30-62/ton for meal. Part of this advantage is due to improvements in amino acid digestibility, including cysteine.

For more information on digestibility or how our processing techniques can benefit your operation, please contact a member of our team.