Real-Time Quality Control: The Standard for Soy Processing Plants

Customers frequently ask us, “what rapid/real-time sample testing ensures consistent feed quality and nutritional precision for my high-shear dry extruded soymeal?” Along with answering which analyses correlate to soymeal quality, it is important to address the types of tests as well as their advantages and disadvantages. These are well-established tools in the industry, with two of the most common methods for soy ingredients being colorimetric tests and NIR (Near-Infrared Reflectance).

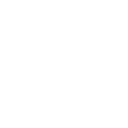

One of the most widely used methods is the colorimetric test, which estimates urease activity in raw and processed soymeal. Urease activity is one indicator of proper thermal processing. A sample of extruded soy is added to a dish, then a color-changing substrate is introduced. In 5 minutes or less, the sample will change color in response to urease activity – see the photo below.

The advantage to this is the simplicity and ease of the test to quickly determine a “yes” or “no” on whether urease activity is present. However, the major downside to this process is that this does not quantify the amount of urease remaining. Additionally, urease alone cannot be a good indicator of other antinutrient activity, such as trypsin inhibitors, therefore urease testing alone cannot fully guarantee that the soymeal is properly processed.

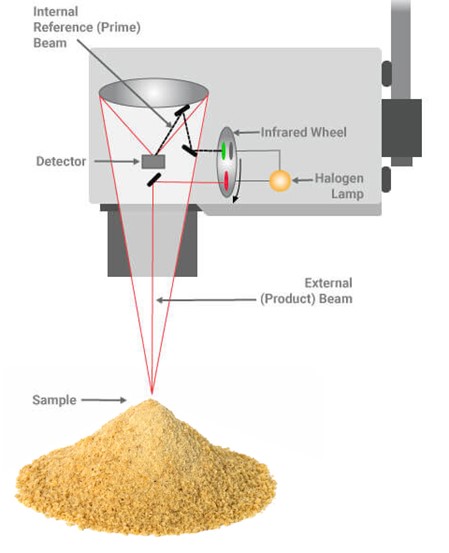

Another commonly used method is Near-Infrared Reflectance (NIR) analysis, which can estimate chemical composition (i.e. moisture, fat, protein, fiber, starch content) using a small device or sensor. This data can then be exported, and reports generated from the findings. The main advantage with NIR testing is the real-time data which allows processors to detect changes in their finished product and make the proper adjustments accordingly on the spot.

Many operations now utilize NIR analyzers within their processing line, allowing constant live feedback. This allows faster analysis over the typical benchtop NIR testing. Despite NIR’s rapid data analysis, the drawback of NIR testing is the calibration, as its values are merely estimates. And as estimates, the calibration is sensitive to changes in the sample, such as temperature, color, particle size, etc. As such, NIR analyzers do not have a universal calibration model, which can cause issues with accuracy in the results.

However, ongoing advancements in NIR analysis improves its weak points, such as:

- Faster Scanning Speeds: Modern in-line NIR sensors can provide a full chemical scan every 1–2 seconds, dramatically improving responsiveness.

- Wider Calibration Libraries: Some providers now offer pre-built calibration libraries specifically for soy-based ingredients, reducing calibration times.

- Self-Cleaning Sensors: Some newer models include self-cleaning optics to prevent build-up of product dust or debris inside equipment that could interfere with accurate measurements.

To overcome some of the disadvantages highlighted above, established practices such as maintaining consistent operating parameters and verifying results through laboratory validation remain critical. Additionally, validation by lab testing is essential to confirming real-time observations and should be a part of the quality management.

Insta-Pro®’s ExPress® system is scientifically-proven – backed with over 50 years of research – to deliver consistent and high-quality ingredients under the recommended processing parameters, allowing more consistency to end products. Speak with Insta-Pro technician today to learn more about proper processing guidelines.