Preserving Identity with High-Shear Dry Extrusion

Soybeans are not created equal. High-quality, identity-preserved soybeans like non-GMO, organic, or high-protein varieties offer distinct advantages in nutrition and traceability. However, preserving the integrity of these soybeans through processing is a challenge. As described in previous blogs, traditional processing methods degrade nutritional value via chemical solvents or excessive heat, which compromise the preservation of proteins and nutrients inherent in soybean varieties.

We understand the importance of maintaining soybean identity from farm to final product. Since our inception, Insta-Pro’s team of nutritionists and engineers have strived to achieve the best method for producing high-quality ingredients while preserving nutritional quality. High-shear dry extrusion (HSDE) via an Insta-Pro extruder provides a solution that not only enhances the nutritional availability of soybeans for animals but also ensures that unique characteristics remain intact.

How High-Shear Dry Extrusion Works to Protect Soybean Quality

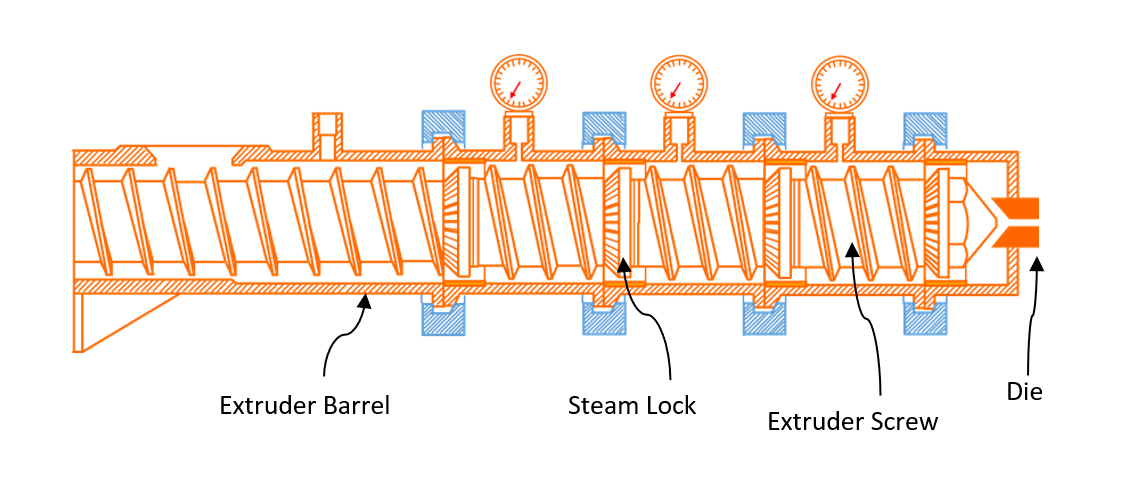

The process begins by feeding the soybeans through the extruder barrel, where shear forces are applied by the rotating barrel screw. These forces break down the beans and expose them to heat, which is generated by friction between the screw and the barrel walls. The heat produced during this phase is critical for the High-Temperature Short-Time (HTST) process, which ensures the soybeans are thoroughly cooked.

The precise method of heating and cooking allows the beans to reach the necessary temperature to eliminate harmful microbes, deactivate anti-nutritional factors, and improve digestibility. However, the time spent at high temperatures is intentionally kept just long enough to fully cook the beans without compromising the integrity of heat-sensitive amino acids such as lysine and methionine. These amino acids are crucial to animal nutrition as they play a key role in protein synthesis and overall growth.

Moreover, because the soybeans are processed without the use of chemicals or solvents, there is no risk of contamination from synthetic additives, which maintains the natural nutritional profile of the soybeans. This process is also compatible with organic certification standards, ensuring that the final product meets the strict requirements for organic feed production.

The Key Factors in Identity Preservation for Processors

- Chemical-Free, Mechanical Processing

Unlike traditional solvent extraction, processing relies on mechanical extrusion and pressing. This friction-based approach generates the necessary heat and pressure to rupture oil cells while preserving the soybean’s inherent characteristics. By avoiding chemical solvents, this method retains the natural composition of the soybean, ensuring a cleaner, more natural product that aligns with consumer demand for minimally processed ingredients. - Retaining Nutritional Value

The HTST method optimizes the deactivation of anti-nutritional factors while preserving essential nutrients, protein quality, and digestibility energy. Internal and independent research has consistently shown that ExPress® soymeal provides superior amino acid availability compared to conventionally processed meal, with a 92% Amino Acid digestibility and 85% deactivation of anti-nutritional factors, making it an excellent choice for feed applications across livestock species.

- Scalability for Specialty Markets

Unlike solvent extraction plants, which require high capital investment and continuous large-batch processing to achieve economic viability, our systems allow for flexible, small- to mid-scale operations with significantly lower operating costs. Additionally, eliminating solvent extraction simplifies the plant design and reduces environmental compliance requirements. This is particularly advantageous for processors serving small or niche markets like organic and specialty feeds, where preventing cross-contamination is critical. Precise control over processing conditions additionally ensures consistent product quality while allowing for scaling based on market demand.

With our technologies, processors can ensure the integrity of their soybeans while elevating product quality at scale. Reach out to discover how we can help you unlock the full potential of your specialty soybeans. Our engineering team is ready to support you with project feasibility assessments and customized layout quotes.