Antinutrients Part II: Variation Among Mechanically-Processed Soy Products

As discussed in Part I of a previous blog, urease activity is useful to determine if the soy product was cooked adequately to reduce ANFs, however, it is not useful in determining if the heating process damaged soy proteins. While thermal treatment of soybeans is required to lower antinutritional factors (ANF), over-exposure to heat treatment can damage proteins due to the Maillard reaction. This reduces the protein digestibility (and essential amino acids) and can cause off-flavors and darker colors to the meal.

Recently, an article was published revealing soy products exhibit variation in ANFs and nutrient digestibility based on the type of processing used. More specifically, full-fat soy and mechanically-defatted soy meals may have differences in their ANFs and protein digestion due to variation in their processing methods. An exception are soybeans properly processed though high-shear dry extrusion – a well-controlled process. The extruded soy products when processed under the recommended parameters have minimal variation in nutritional quality between batches and plant locations of both extruded full-fat and ExPress® soy meals.

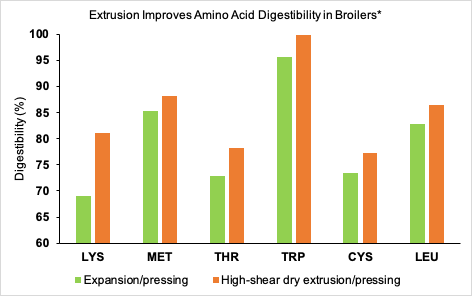

Lysine – a limiting amino acid – is particularly susceptible to a Maillard reaction caused by prolonged heat treatment. In the graph below, lysine digestibility was improved by 12% points in broilers fed extruded meal versus meal processed via expansion – lower processing temperatures than extrusion for 1-2 minutes. This effect is even more pronounced with prolonged heating processes like roasting and toasting. To ensure consistent, high-quality ingredients, why would you not choose high-shear dry extrusion?