Corn Particle Size Improves Swine Digestibility for Producer Savings

The particle size of corn and other cereal grains is a key factor to consider, given that it affects nutrient digestibility and growth performance of pigs. Grinding corn to reduce particle size increases the surface area, which allows more activity of digestive enzymes, resulting in improved feed efficiency.

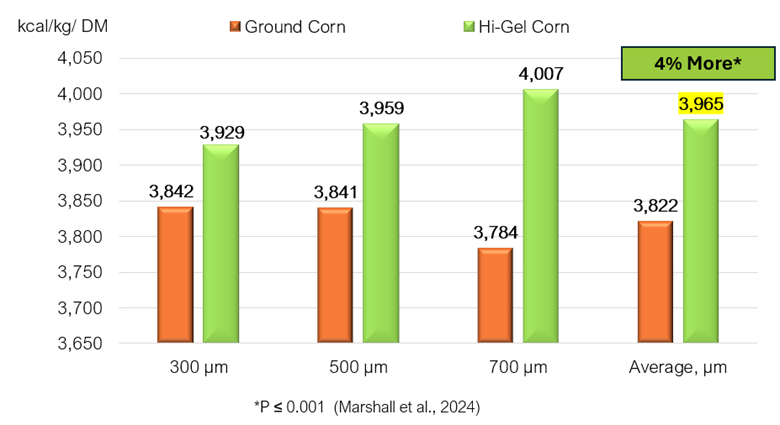

Considering the potential effects of particle size of corn on the animal response, a trial was conducted at the University of Illinois to determine the effects of reducing the particle size of Hi-Gel™ Corn (high-shear dry extruded) and ground corn (non-extruded) on energy digestibility and concentrations of metabolizable energy in pigs. To accomplish it, both sources of corn were ground to three different particle sizes (300, 500, and 700 µm) and fed to nursery pigs. The digestibility of the gross energy of Hi-Gel™ corn was 6% higher and the metabolizable energy concentration was 4% higher than that of ground corn (non-extruded) independently of the particle size, as observed below.

Overall, results from this trial to determine how the particle size of Hi-Gel™ corn affects the energy value of corn for pigs indicate that high-shear dry extrusion technology adds energy value to corn, making the highly gelatinized starch more digestible for productive purposes, regardless of particle size.

As dry extrusion increases the available energy in corn, it is possible to get more energy out of Hi-Gel™ corn, which allows for diet cost savings. The economic benefits of higher metabolizable energy in Hi-Gel™ Corn is an opportunity for swine integrators to save approximately 3.5% on feed costs for nursery pigs with less inclusion of SBM and oil in the diets.

This promising new data adds to our growing insight into extruding corn, and we are excited to continue exploring this invaluable ingredient for improving animal nutrition.