How a Decanter Works

April 14, 2016

The process of mechanical oil pressing yields two final products: meal and oil. With our customers, the meal is typically the primary product, but some producers target the…

April 14, 2016

The process of mechanical oil pressing yields two final products: meal and oil. With our customers, the meal is typically the primary product, but some producers target the…

March 25, 2016

There has been a lot of interest lately from existing oil press owners, concerning what is required to process different types of oil seed through their systems. The…

January 7, 2016

The popularity of producing shaped products and feeds is increasing. This includes pet foods, fish feed, and treats. While end products are vastly different, inputs determine the final…

December 17, 2015

In part 1 of this series on coolers, we discussed the use of rotary drum and counterflow coolers when cooling extruded and/or pressed oilseeds. In Part 2, we…

December 10, 2015

When using high shear dry extrusion for oilseed processing, the final product typically only needs to be cooled. This is the case when making either full fat soya (FFS)…

November 5, 2015

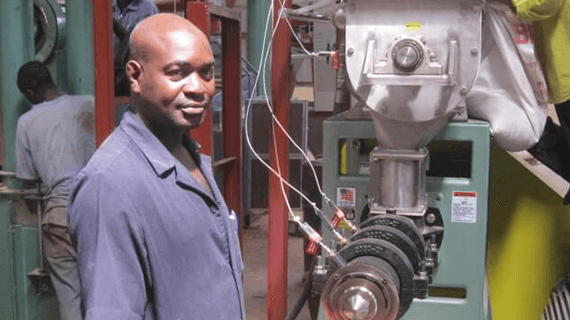

I’ve traveled a lot over the years, but this trip was special in that it was my first start-up for our new Model MS3000 medium shear extruder. We…

August 27, 2015

I have traveled to several countries over the last few years and have seen a big difference in the safety practices in processing facilities. Safety is a job…

July 23, 2015

Housekeeping is valuable for many reasons. • It is much easier to repair clean equipment • A dirty machine has to be cleaned prior to working on it…

July 16, 2015

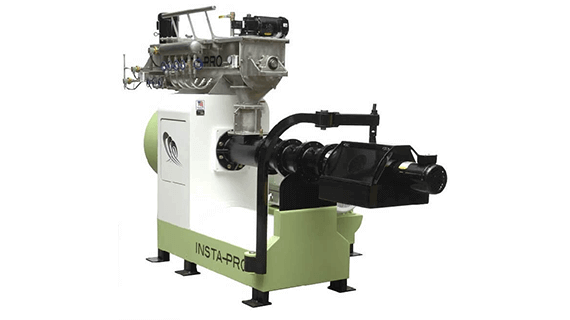

Extrusion machine operators are usually looking for, and find ways to make, extrusion machines more efficient or more convenient to use. Insta-Pro Intl extruders are known to endure through years…

June 4, 2015

We often discuss the importance of developing a partnership with our customers, but another very important relationship is the one we have with our vendors. Without strategic partners,…

May 14, 2015

In a previous blog, I discussed how operators play a key role in running an efficient operation. This week I will take that discussion a step farther and outline…

April 23, 2015

High quality equipment, ingredients and employees are three main factors that go into running a successful business. One thing I have noticed over the years is that while…

April 2, 2015

Equipment and employee safety is key in maintaining a successful business. In a previous blog I discussed the need for proper equipment cleaning, but I did not address on…

February 26, 2015

Scheduled maintenance to avoid down time is important to an operation because it proactively identifies issues, minimizes the risk of uncontrolled down time and avoids costly repairs. Depending…

January 14, 2015

“Why do I need to cool extruded products?” The answer is simple; it controls the water activity, product quality and nutrient value; all important aspects in producing a…

December 18, 2014

You have decided to purchase new equipment to grow your business. The next step in making your business operation a reality, is completing the start-up appointment with trained…

October 30, 2014

I recently spoke with one of our customers, and the topic of shipping costs came up. He relayed to me some information on this expense, and I was…

October 23, 2014

We have all done it. We know our equipment will need new parts soon but you put off ordering them until your machine breaks down and you really…