How Does High-Shear Dry Extrusion Create Rumen By-Pass Fat in Soy?

We know that high-shear dry extrusion from Insta-Pro® is used to improve raw materials. Our philosophy has not changed since the early 1970’s – let the animals tell us the story through feeding trials. Animals don’t lie. But there are ways we can add to what we know – more on that below.

We’ve known for a few years that high-shear dry extruded/partially-deoiled (ExPress®) soy meal likely produces rumen by-pass fat – and that more thorough high-shear dry extrusion conditions seem to produce more rumen by-pass fat. Dairy cows often have a source of rumen by-pass fat in the formulation in order to supply greater amounts of fat to the cow and boost production. But these ingredients are expensive.

We also know from recent work we conducted at Penn State University that ExPress® soy meal, when placed into the rumen of dairy cows, resists digestion.

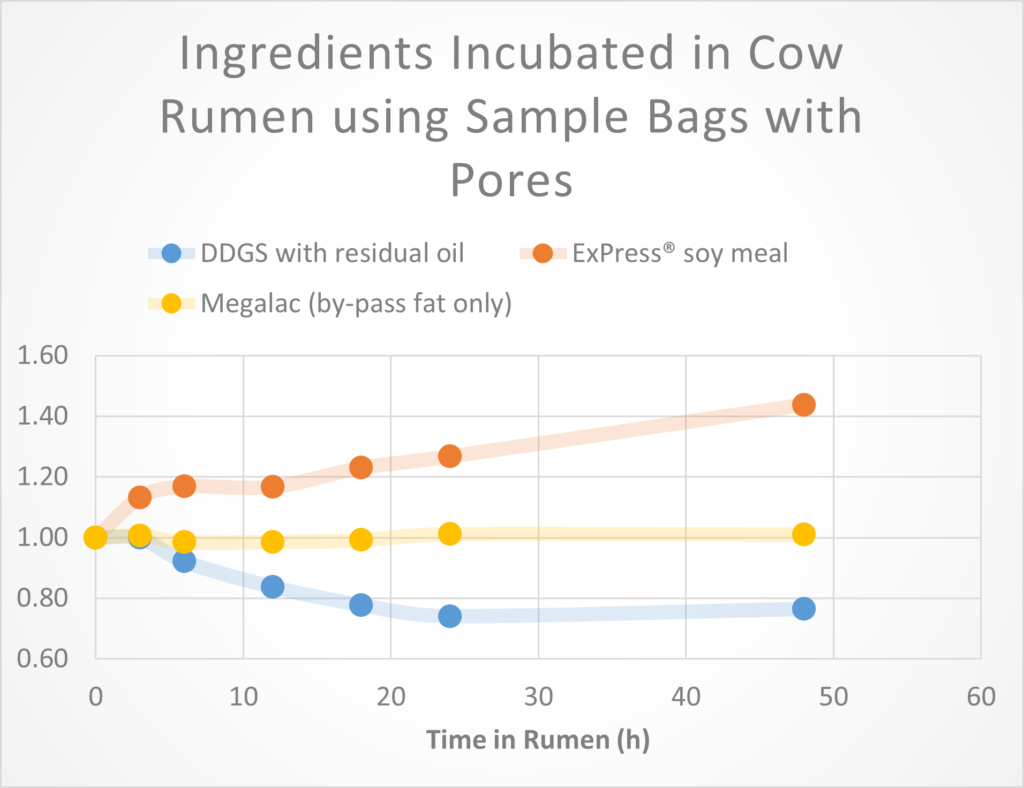

The residual oil in ExPress® soy meal concentrates over time as other components, like carbohydrates, are degraded in the rumen. Thus, ExPress® soy meal is an excellent source of rumen by-pass fat. Megalac®, a source of by-pass fat, remains stable in the rumen, while DDGS residual oil is quickly degraded by the rumen, indicating that it is a poor source of rumen by-pass fat. Data from Penn State University.

It’s another sign that we’re achieving these goals because the same cannot be said for other common ingredients – for example, when DDGS were placed into the rumen and incubated over time, the amount of fat declined quickly, indicating that the rumen bacteria degraded it before it got to the cow (see above). Hence, DDGS do not contain any rumen by-pass fat to speak of.

So, what happens during high-shear dry extrusion that helps make the fat more usable by the cow? Here is a link to an extrusion paper that helps explain this phenomenon. Animal response data is the cornerstone of what we do, but the more evidence that we bring to light in order to support our claims, the better off we are – and more importantly, the better it is for our customers.

In this extrusion research, different levels of starch were blended with different types of fats and oils, and the blends were extruded. When the chemical and binding properties of the extruded materials were examined, complexes were indeed formed between starch and the fats, proving that these new molecules were stuck together by chemical bonds.